Conservation work on the Peter H. Raven Library’s copy of The Orchidaceae of Mexico and Guatemala has begun! Follow along as we document this painstaking restoration of one of the largest and grandest volumes in the Garden’s rare book collection.

The Peter H Raven Library’s copy of Bateman’s Orchidaceae of Mexico and Guatemala was issued in several parts in the 1830s and 40s. During this period, paper was still being made out of relatively pure sources of cellulose, typically cotton and linen rags. Papers made out of these materials are usually very durable and remain bright and flexible as they age, which is why the poor condition of the paper in our copy of Bateman is a bit of a mystery. We reviewed several possible causes of paper degradation in our last blog, but in this blog we are going to zero in on paper size as a potential bad actor.

What is Paper Size?

Most papers contain size. This is a substance added to paper to make it less absorbent. Without size, the cellulose fibers in paper exert a strong capillary pull on liquids, causing them to spread in all directions. It would be impossible to write a letter in pen and ink on unsized paper.

Sometimes paper is deliberately left unsized or lightly sized, as in the case of paper towels or some papers used in printmaking or sumi painting, but that is not the norm.

In Europe and America, the traditional paper size has been gelatin, a protein-based material extracted from the skins, bones and muscles of animals by cooking them in water. Hand-made papers would be dipped into a vat of liquid gelatin after they had been dried. They were then dried again before being sorted, polished and sold.

Machine-made Paper Needed a New Kind of Size

The first machine for making paper was invented in 1798 by a Frenchman named Nicolas-Louis Robert. By the beginning of the 19th century, several designs for paper-making machines had been tried and put into production. The advent of automation changed the nature of paper and even altered some of its chemical content.

Machines make paper in long ribbons, not individual sheets, and a long ribbon can’t be dipped in a vat of gelatin, so a different kind of size had to be used. In 1807, a German named Moritz Illig proposed treating wet paper fibers with alum (an aluminum salt) and then adding rosin soap. The alum would act as a mordant, causing the rosin to stick to the paper fibers throughout the paper-making process, until a final heat treatment melted the rosin into the paper. Alum-rosin size became standard in machine-made paper in the 19th century.

It turned out that the introduction of alum-rosin size was a big mistake. Papers made with it became yellow and brittle due to the acidic nature of alum. Even papers made from rags could be adversely affected by this size.

Is Bateman’s Paper Machine-made?

Given the date of its manufacture, we have been assuming that the paper in Bateman was made from rags, but is it possible that is contains alum-rosin size? Was it made on a machine? If it was made on a machine, it would have to be alum-rosin sized, which would help explain its poor condition.

The paper in Bateman’s book certainly has the look of machine-made paper. It is very uniform in appearance and much of it has a smooth surface, a common characteristic of machine-made paper, which was often run through rollers to give it what is known as a calendared surface.

Testing

We decided to do some chemical tests on Bateman’s paper. First we would test for the presence of gelatin and then for alum.

There are 3 kinds of paper in the book:

- A heavy, somewhat textured paper for the lithographs

- A smooth mid-weight paper for the text

- A very smooth light-weight paper covering the lithographs

We have been collecting small bits of each kind of paper during the course of treatment. Don’t worry! We didn’t deliberately cut pieces off; we found these in the gutter of the book and could not discover where they belonged.

First, the gelatin test. A positive test would indicate the likelihood that the paper was hand-made and that it did not contain alum-rosin size. In that case, size has not been contributing to the papers’ poor condition.

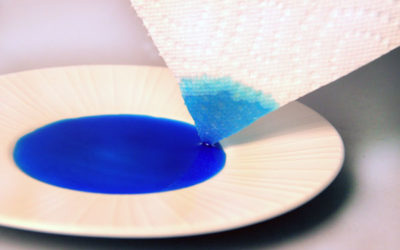

We used a testing method described by Cathleen Baker in her book, From the Hand to the Machine. First copper sulfate and then sodium hydroxide (both in solution) were applied to the paper pieces. A positive result (gelatin present) would show violet. This is a new piece of Whatman filter paper sized with a 2% solution of gelatin.

A negative result (no gelatin) would look sky blue.

All three kinds of paper were tested. There were no positive results.

These results were a surprise, as we had thought it possible that the lithographs at least were printed on hand-made, gelatin-sized paper.

It is important to keep these results in perspective. This testing method was not the most sensitive, we tested only a few pieces, and the yellow tone of the paper could have complicated the color reading. It is also possible that gelatin may have been applied by brush to parts of the lithographs that weren’t tested. Still, these results are interesting.

Next up is the alum test. After this second test, we may feel like we can make some tentative conclusions about the paper in Bateman’s Orchidaceae of Mexico and Guatemala.

Next up: Alum Testing

Learn more about the restoration of the Bateman book:

Part 1 | Part 2 | Part 3 |Part 4 |Part 5 | Part 6 | Part 7

Leave a Reply